Alpha Plaster Calcining

Alpha Plaster Calcining

Alpha Plaster Calcining

Chayaphol proudly presents its Alpha Plaster Calcining Plant, designed to meet the growing demand for high-quality Alpha Plaster in industries requiring precision and durability. With cutting-edge technology and engineering expertise, our plant ensures superior performance and efficiency in producing premium-grade Alpha Plaster.

How Does It Work?

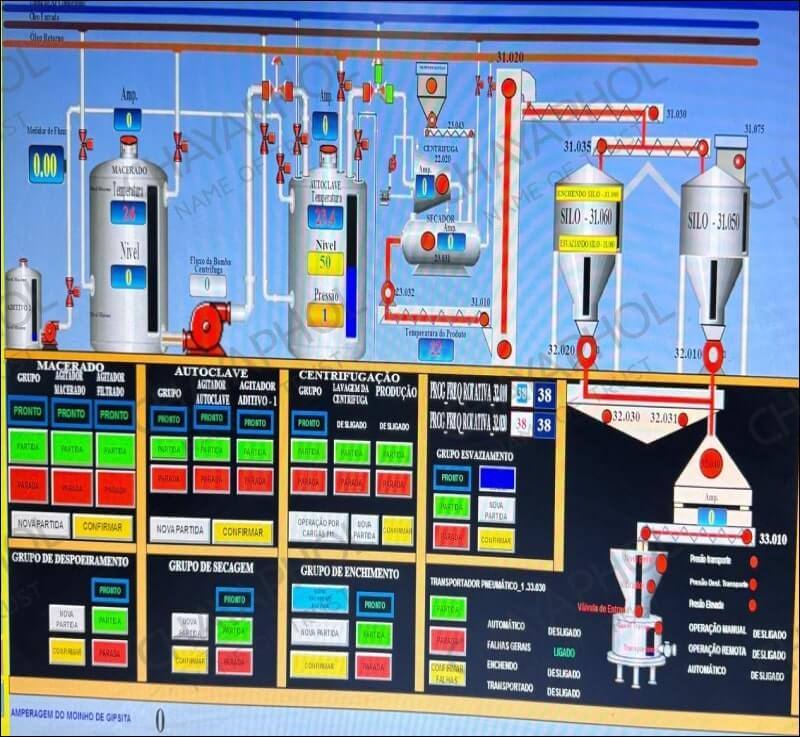

- Raw Material Preparation: High-purity gypsum is crushed and screened for uniformity.

- Calcination: Gypsum is heated in autoclaves under precise temperature and muti step pressure, holding and transforming it into Alpha Hemihydrate crystal with is confirm by microscope

- Drying: The material is dried to minimized free water.

- Grinding and Classification: The product is finely ground and classified for consistency.

- Quality Control: Rigorous process control and testing ensures super high strength of out standing plaster quality named alpha plaster.

ALPHA PLASTER CALCINING PACKAGE

Feel free to customize this content further to fit your website’s style and specific offerings

| Model | Capacity (Ton/hour) | Types of Energy |

| AP02 | 0.2 | Natural Gas, LPG, Coal, Oil, Biomass |

| AP05 | 0.5 | Natural Gas, LPG, Coal, Oil, Biomass |

| AP10 | 1 | Natural Gas, LPG, Coal, Oil, Biomass |

Applications

- Several Moulding plaster application such as sanitary ware, table ware, jiggering, ETC.

- Super hard alpha plaster is popular for high end casting process like a dental plaster and another medical plaster.