Dry board handing

Dry Board Handing

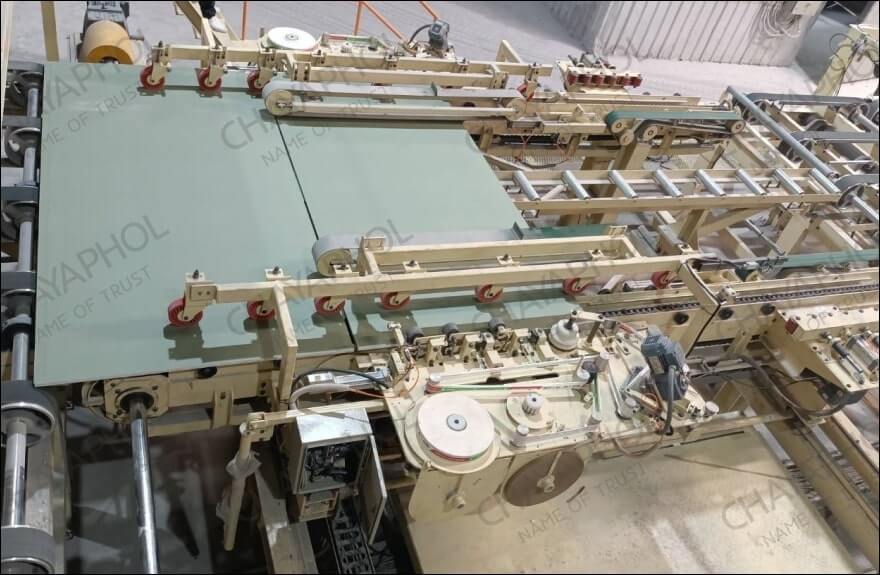

Dry Board Handling for Gypsum Board

At Chayaphol, we are dedicated to enhancing the efficiency and quality of the gypsum board manufacturing process. We also provide the customized supply of the below equipment.

- Outfeed

- Cascade

- Cross conveyor 3

- Reject

- Booker arm

- Trimsaw & taping machine

- Stacker feeder

- Stacker

Importance of Dry Board Handling

Once gypsum boards are dried and cured, proper handling is crucial to maintain their integrity and quality. Effective dry board handling prevents damage, ensures smooth operations, and enhances productivity in the manufacturing process. Chayaphol’s solutions are tailored to meet the high demands of modern gypsum board production lines.

Features and Benefits of Chayaphol’s Dry Board Handling Solutions

1. Precise and Damage-Free Handling

- Our advanced handling systems are designed to move dry gypsum boards with precision.

- Ensures minimal impact and reduces the risk of damage during transportation.

2. Enhances workflow efficiency for higher productivity.

- Automated Lifting and Stacking.

- Specialized lifting devices manage the movement of dry boards effectively.

- Automated stackers organize boards, reducing the need for manual labor.

3. Increases throughput by handling large volumes seamlessly.

- Customizable Solutions

- Handling systems are adaptable to various board sizes, weights, and production requirements.

- Offers flexibility and scalability to suit different manufacturing setups.

4. Advanced Control and Monitoring

- Features advanced control systems for real-time monitoring and adjustment.

- Ensures smooth operation and maximizes system efficiency.