Gypsum Plant Automation

Gypsum Plant Automation:

Enhancing Efficiency and Performance

Gypsum plant automation is revolutionizing the gypsum board production industry by integrating advanced technologies to streamline operations, enhance efficiency, and reduce costs.

Automation in gypsum plants encompasses various aspects, from raw material handling to finished product delivery, ensuring consistency and quality in production processes.

Key Benefits of Automation in Gypsum Plants

- Increased Production Efficiency Automation systems allow for continuous operation with minimal human intervention, significantly increasing production rates and reducing downtime. Automated systems can handle tasks such as material mixing, board forming, and drying with precision and speed.

- Enhanced Quality Control Implementing automated quality control systems ensures that each gypsum board meets the required standards. Advanced sensors and monitoring equipment detect and correct any deviations in real-time, maintaining high product quality.

- Cost Reduction Automation reduces labor costs by minimizing the need for manual labour. It also optimizes resource usage, reducing waste and energy consumption. These efficiencies lead to lower overall production costs.

- Data-Driven Insights Modern automation systems collect and analyse vast amounts of data from various stages of the production process. This data can be used to optimize operations, predict maintenance needs, and improve decision-making processes.

Implementation of Automation in Gypsum Plants

- Increased Production Efficiency Automation systems allow for continuous operation with minimal human intervention, significantly increasing production rates and reducing downtime. Automated systems can handle tasks such as material mixing, board forming, and drying with precision and speed.

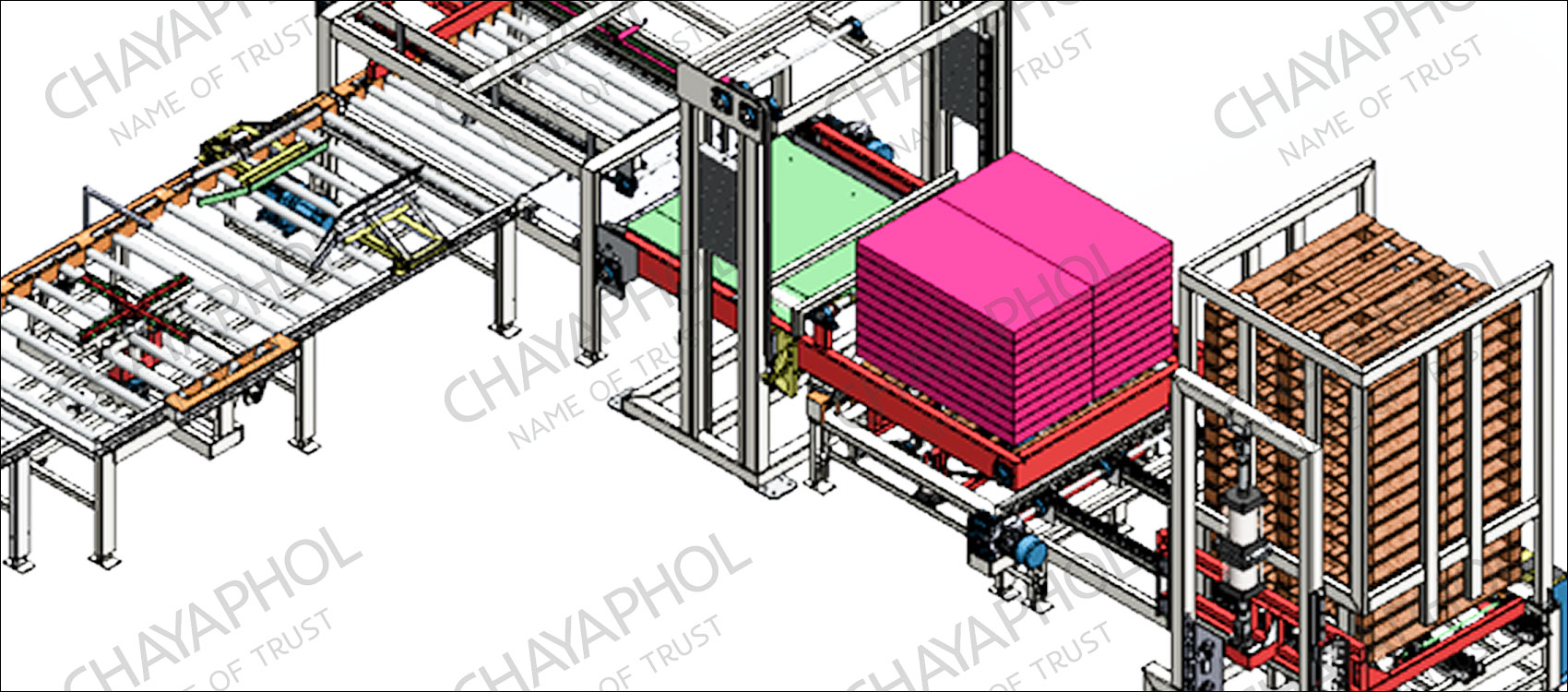

- Production Line Automation Key production processes such as mixing, board forming, and drying are automated using advanced machinery and control systems. This ensures uniformity and precision in the production of gypsum boards.

- Quality Control Systems Automated inspection systems use cameras and sensors to monitor the quality of gypsum boards in real-time. Any defects are identified and rectified immediately, ensuring only high-quality products reach the market.

- Packaging and Distribution Automation extends to the packaging and distribution phases, with automated stacking, wrapping, and labeling systems. These systems ensure that products are packaged securely and efficiently, ready for shipment.