Hammer mills calcining

Hammer mills calcining

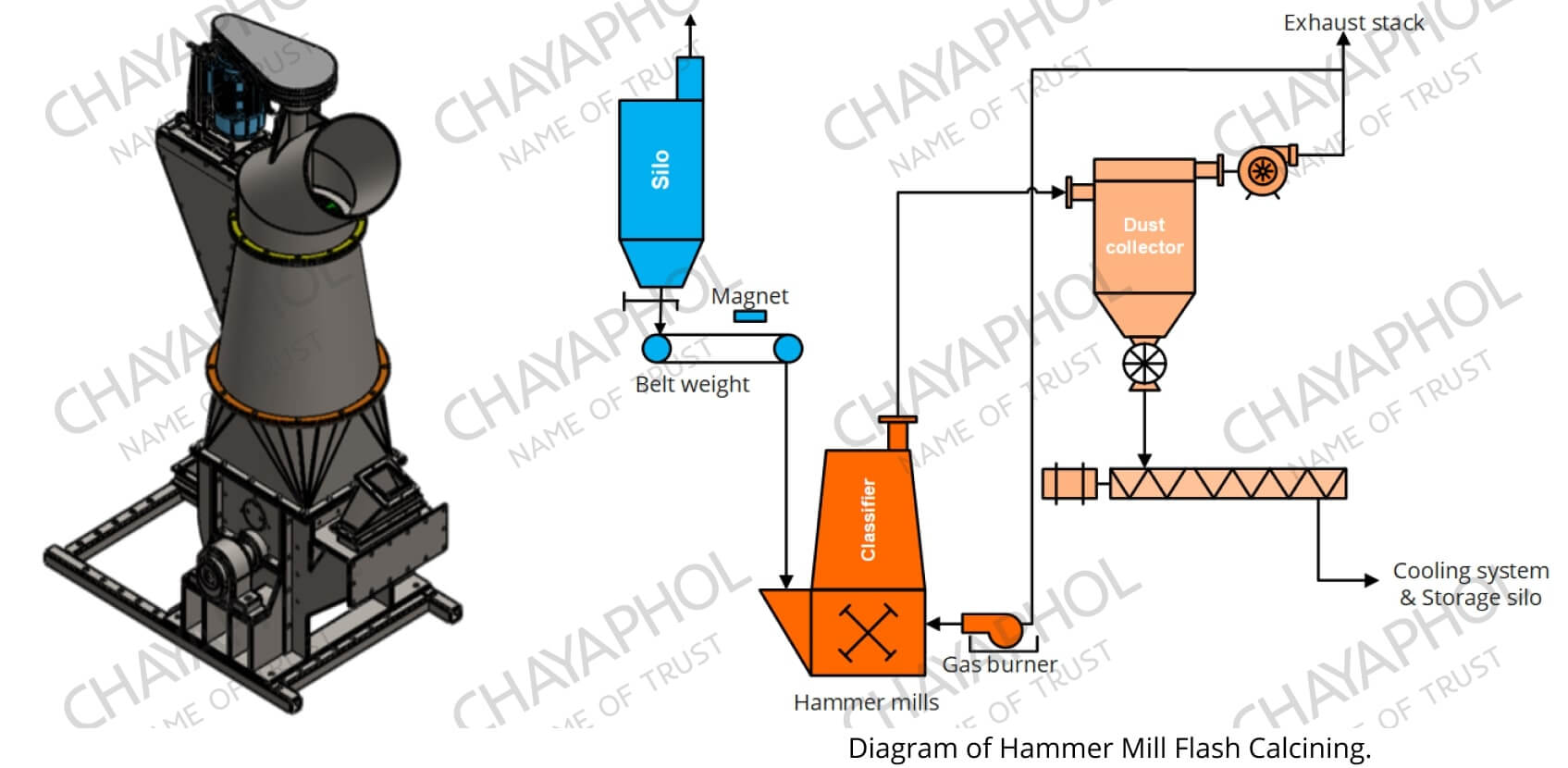

Hammer Mill Flash Calcining by Chayaphol

Hammer mill calcination utilizes rapid heating to convert raw materials into a more useful form, often associated with minerals such as gypsum or lime. This technique can be effectively applied in the production of high-quality calcined products. By employing flash calcining methods, materials are subjected to elevated temperatures for short durations, ensuring quick and uniform heat transfer.

Hammer Mill Flash Calcining

- Gypsum Production: Enhancing the quality of gypsum for construction materials.

- Lime Processing: Producing quicklime from limestone for various industrial applications.

- Mineral Processing: Effective for other minerals requiring quick thermal treatment.

Over Kettle Calcining Methods

1. Speed and Efficiency

- Flash Calcining: Offers rapid processing at high temperatures, making it ideal for high-volume production where speed is a priority.

- Kettle Calcining: Slower, more controlled heating results in lower throughput but allows for a more uniform product.

2. Product Quality

- Flash Calcining: Produces a more porous gypsum, beneficial for applications needing high reactivity, like certain plasters.

- Kettle Calcining: Yields denser, consistent gypsum, ideal for wallboard, where strength and uniformity are key.

3. Energy Use

- Flash Calcining: Higher temperatures lead to increased energy use, but quick processing makes it relatively efficient per unit.

- Kettle Calcining: Lower temperatures reduce energy demand, making it more efficient when slower production is acceptable.

4. Application Suitability

- Flash Calcining: Best for reactive, lightweight products like specialized cements.

- Kettle Calcining: Preferred in wallboard and construction applications needing high durability.