Kettle calciner

Kettle calciner

Kettle Calciner

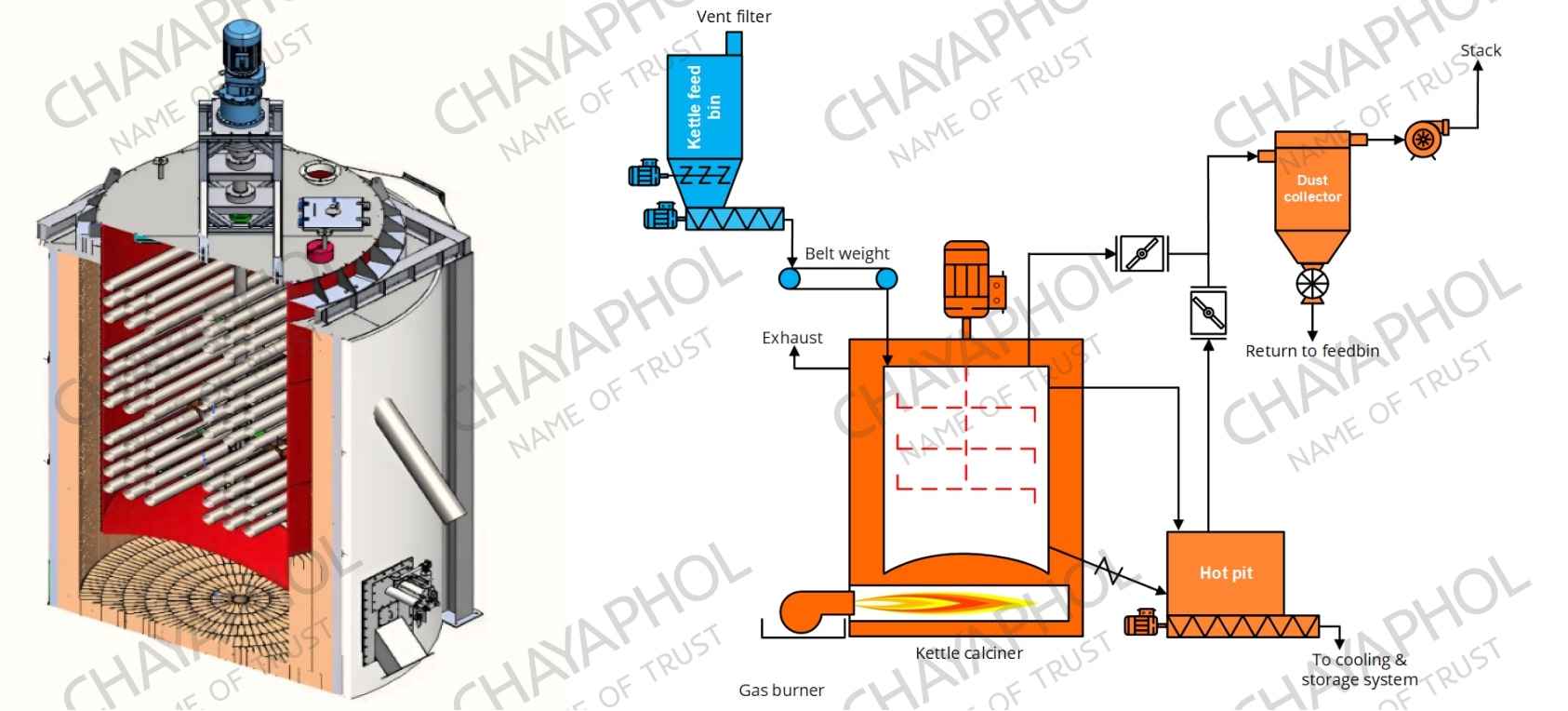

A Kettle Calciner is a specialized machine designed for heating gypsum to produce plaster. This process, called calcination, transforms gypsum into a powdery material used in construction, decorative applications, and gypsum board manufacturing. The Kettle Calciner’s indirect heating method ensures the gypsum is processed evenly, resulting in reliable, high-quality plaster.

How Does It Work?

- Loading the Gypsum: Crushed gypsum is added to the calciner’s kettle, a large, enclosed steel tank.

- Heating Process: The kettle is surrounded by an indirect heating system. This ensures that the gypsum is gently and evenly heated without burning.

- Transformation into Plaster: As the temperature reaches around 150-180°C, the gypsum loses water and transforms into plaster of Paris (hemihydrate gypsum).

- Mixing System: Agitators inside the kettle keep the gypsum moving, ensuring uniform heating and preventing clumps.

- Plaster Discharge: Once ready, the finished plaster is automatically released and is ready for use or packaging.

Compare to Flash Calcining?

Kettle Calciner:

- Produces plaster with superior quality for decorative and construction purposes.

- Suitable for gypsum boards, but the final product is slightly less refined than that made with flash-calcined plaster.

Flash Calcining:

- Designed specifically for gypsum board production, producing plaster with excellent bonding strength and faster drying times.

- Less suitable for high-precision decorative applications.

In summary, the Kettle Calciner is a versatile solution for producing high-quality plaster. While it may not match the Flash Calcining for gypsum board production, it’s a reliable and efficient option for many other applications. Contact us to find out how this system can meet your production needs!