Light weight technology for gypsum board

Light weight technology for gypsum board

Skim coat technology

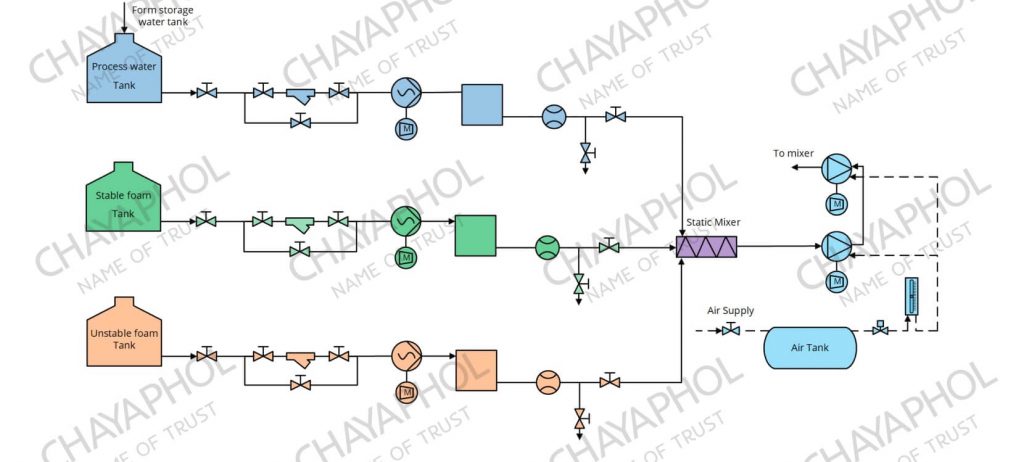

Double foam system

Light weight technology for gypsum board by chayaphol

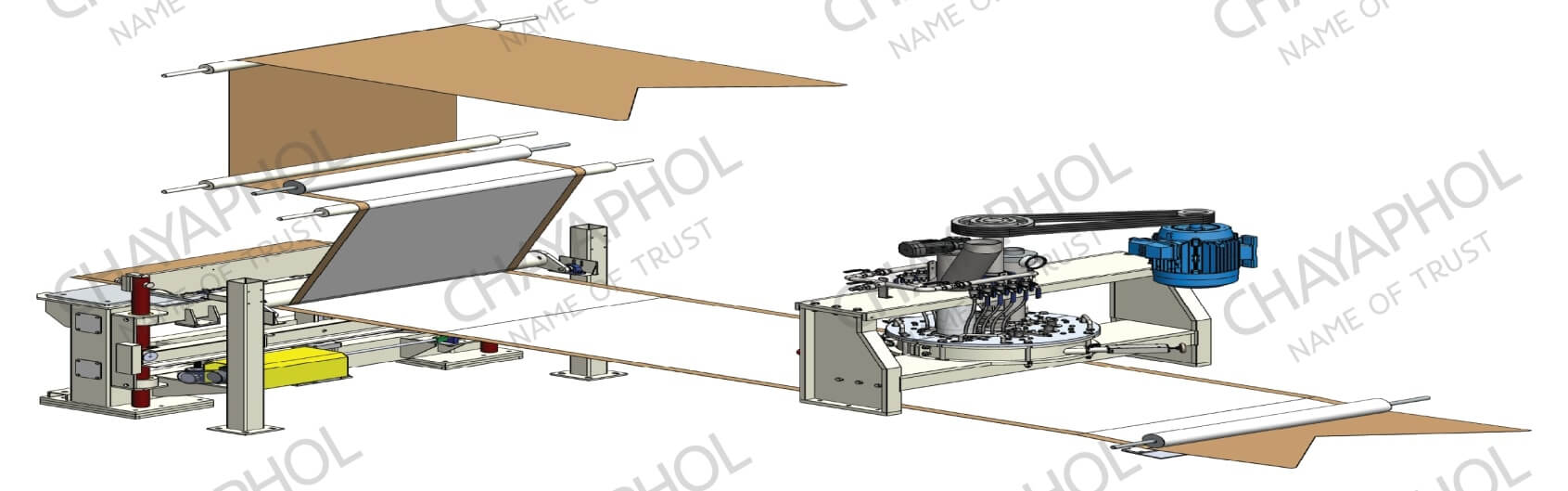

Chayaphol’s skimcoat and foam generator technology enables the production of lightweight gypsum boards while maintaining their original strength. This innovation helps reduce manufacturing costs without compromising quality. We provide supply the below equipment.

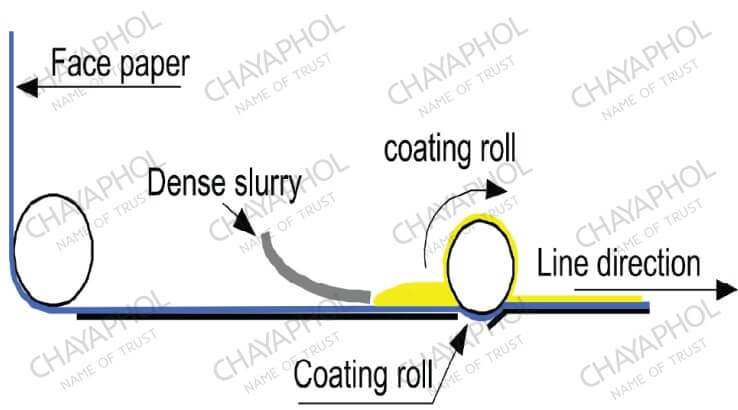

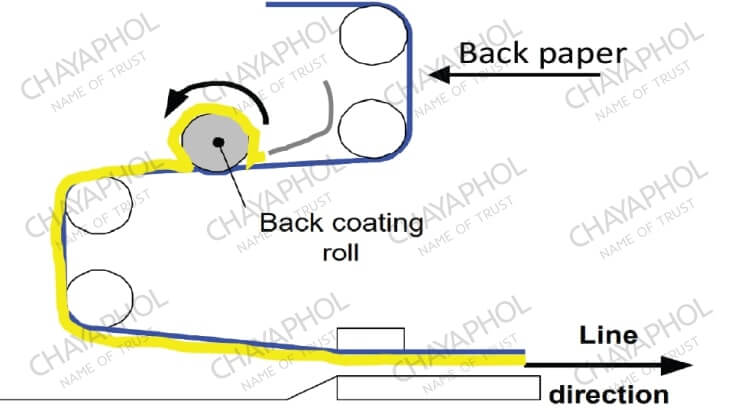

Skim Coat for gypsum board

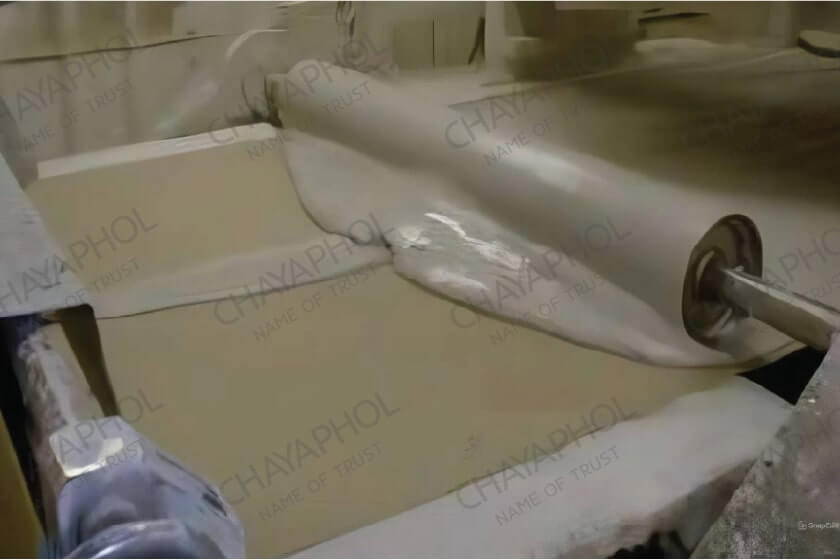

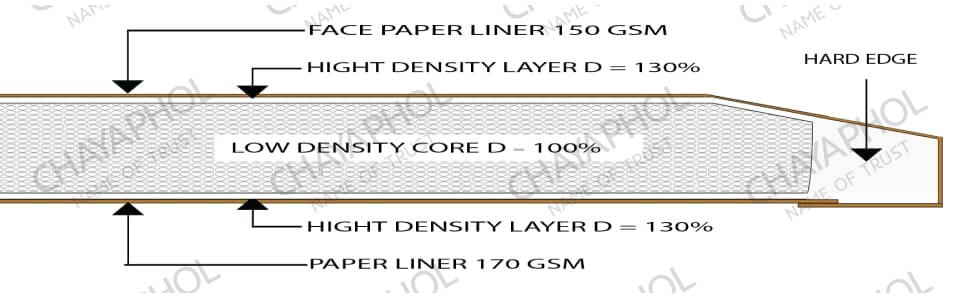

Our Skim Coat Technology ensures a uniform slurry coating on both the top and bottom paper layers of the gypsum board. This coating forms a dense, high-strength layer that bonds seamlessly with the core, which features a lightweight foam structure. By reinforcing the board’s outer layers, the skim coat prevents any reduction in strength, ensuring that the lightweight design does not compromise the board’s strength and performance.

Skim coat explained

Board with skim coat structure

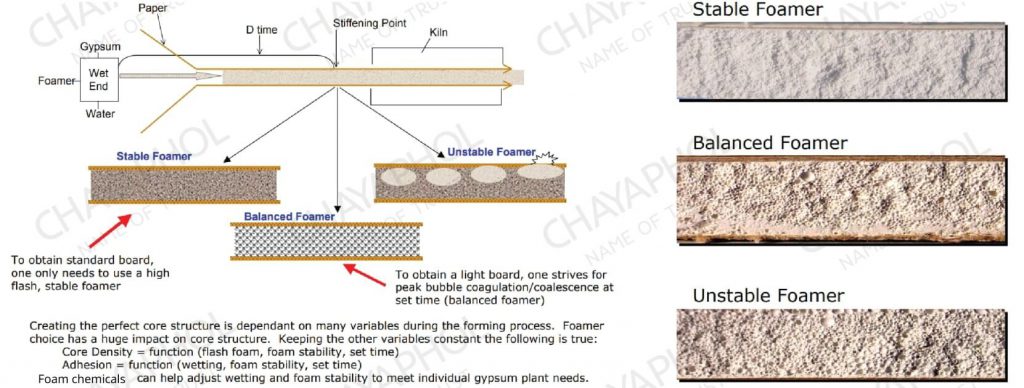

Double foam system for gypsum board

Our Double Foam System Technology creates micro-foam structures in the core of the gypsum board, significantly reducing its overall weight. This innovative approach allows for the production of lighter boards without compromising strength, making it an ideal solution for cost-efficient and high-performance construction materials.

Double foaming system

Diagram of double Foam generator system

Benefits of Skim Coat & Foam Generator

- Reduced Dry Weight: Lowers the dry weight to 6.5 kg/m² at 12.5 mm thickness, making the board lighter.

- Enhanced Bonding: Ensures a strong bond in both dry and humid conditions with a thin, high-density gypsum layer at the paper-core interface.

- Optimized Layer Thickness: Forms a dense layer (~0.5 mm or 2/100 in), improving durability.

- Improved Edge Integrity: Reduces end peeling, enhances bonding, and ensures safer production conditions.

More over Chayaphol services about Skim coat & foam generator

- Stucco quality improvement

- Double foam system implementation

- Mixer improvement

- Formulation improvement