Dryer & heating systems

Dryer & heating systems

Dryer & Heating Systems for Gypsum Board

Chayaphol design and supply 2 types of gypsum board dryer:

- Longitudinal air flow dryer

- Cross air flow dryer

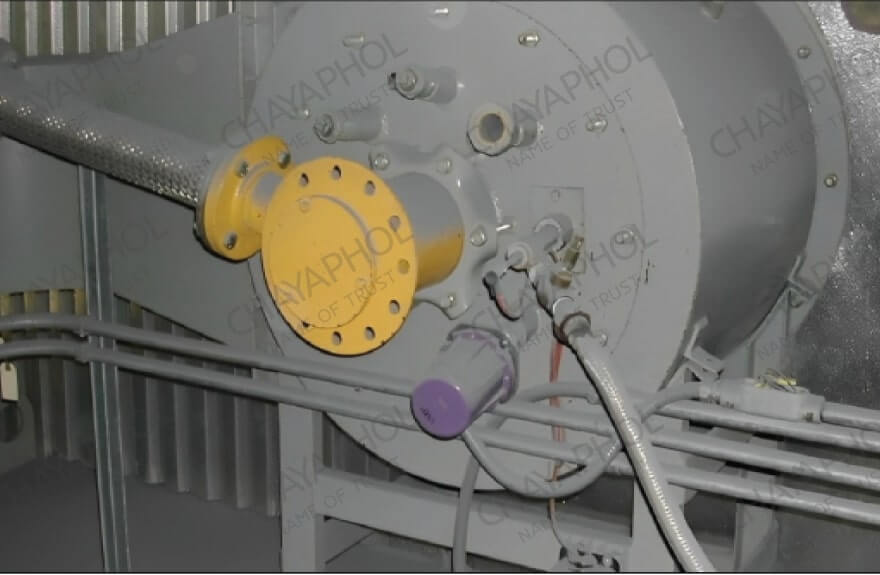

Fuel for dryer: Chayaphol is able to design and select any kind of fuels whatever direct heating or indirect heating, whatever fuel it is, natural gas, LPG, Coal, Fuel oil, Diesel oil, Bio-mass, ETC

More over chayaphol also provide below dryer parts and services.

- Dryer capacity expansion

- Dryer energy improvement

- Dryer efficiency improvement

- Board moisture profile improvement

- Dryer temperature control and display

- Dryer moisture control and display

- Dryer heat recovery system supply

- Dryer fuel switching

- Dryer hybrid fuel

- Dryer chain tension control

- Board gap control

- Dryer part supply

- Dryer spare part supply

Importance of Dryer & Heating Systems

In the production of gypsum boards, proper drying and curing are essential steps to ensure the final product meets industry standards for strength, durability, and dimensional stability. Our Dryer & Heating Systems play a critical role in this process by providing controlled heat and airflow to remove moisture from the boards and facilitate the curing process. This ensures uniform drying, prevents defects, and enhances overall product quality.

Features Dryer & Heating Systems

1. Precise Temperature Control

- Utilizes advanced heating technology for precise temperature regulation.

- Ensures uniform drying and curing of gypsum boards.

2. Optimized Airflow Systems

- Engineered to maximize moisture removal from boards.

- Accelerates the drying process, reducing production cycle times.

- supports Long Flow and Cross Flow designs to suit different production setups.

3. Customizable Design

Tailored to accommodate various production requirements such

- Board thickness

- Production volume

- Desired drying/curing parameters

4. Energy Efficiency

- Designed to minimize energy consumption without sacrificing performance.

- Reduces operating costs while maintaining optimal drying and curing results.

5. Integrated Automation

- Features real-time monitoring and adjustment of drying parameters.

- Ensures consistent performance with minimal manual intervention.

6. Durable and Reliable Construction

- Built with high-quality materials and components.

- Engineered for long-term operation in demanding industrial environments.

7. Benefits

- Long Flow Higher capacity, consistent performance, and ideal for large-scale production.

- Cross Flow Flexible, faster adaptability, and efficient for varied batch sizes.